The characteristics of an ideal AC power supply are stable frequency, stable voltage, zero internal resistance, and a pure sine wave (no distortion). Variable frequency power supply is very close to the ideal AC power supply. Therefore, advanced and developed countries are increasingly using variable frequency power supply as a standard power supply to provide the best power supply environment for electrical appliances and facilitate objective assessment of the technical performance of electrical appliances. Regarding the topic of "the difference between variable frequency power supply and industrial frequency power supply and what is the role of variable frequency power supply", the following will give a detailed introduction.

1. What is a variable frequency power supply

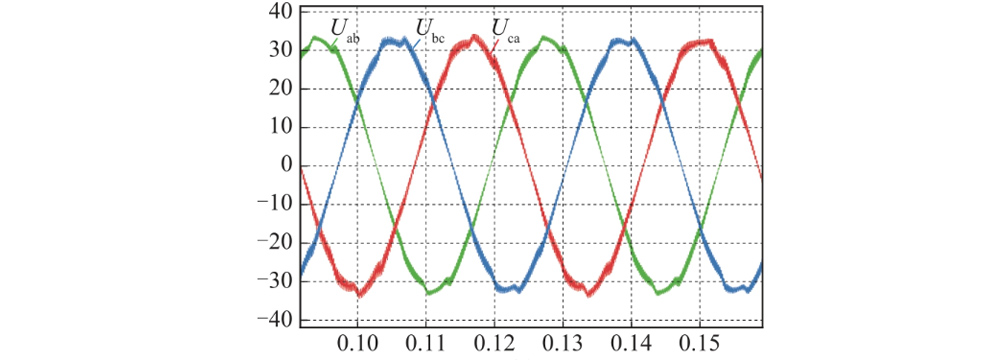

The variable frequency power supply converts the AC power in the city power through AC→DC→AC, and outputs a pure sine wave. The output frequency and voltage are adjustable within a certain range. It is different from the variable frequency speed controller used for motor speed regulation, and it is also different from the ordinary AC voltage regulated power supply. The characteristics of an ideal AC power supply are stable frequency, stable voltage, zero internal resistance, and a pure sine wave (no distortion).

2. What is an industrial frequency power supply

2.1 Definition and use of industrial frequency power supply

Industrial frequency power supply is a device that converts AC power into a DC power supply of the required voltage. It is mainly used in electronic equipment, industrial automation production lines and other fields. It can reduce the voltage, rectify, filter, and process the AC voltage received from the power grid to provide the working voltage and current required for the normal operation of the equipment and products.

2.2 Basic structure and working principle of industrial frequency power supply

Industrial frequency power supply is generally composed of transformer, rectifier circuit, filter circuit, voltage stabilization circuit, etc. Among them, the transformer mainly plays the role of converting the high voltage of the power grid into the low voltage required by the equipment, and the filter circuit can filter out the residual noise signal. During the entire working process, after adjustment by various circuits, the output DC power is maintained within the required voltage and current range.

3. The difference between variable frequency power supply and industrial frequency power supply

The difference between variable frequency power supply and industrial frequency power supply is that the output frequency and voltage of the variable frequency power supply are adjustable within a certain range, while the industrial frequency power supply is fixed and immutable.

The variable frequency power supply converts the AC power in the mains power through AC→DC→AC, and outputs a pure sine wave, and the output frequency and voltage are adjustable within a certain range.

Industrial frequency power supply refers to the power supply that can use the rated frequency for the power generation, transmission, transformation and distribution equipment of the power system and industrial and civil electrical equipment. The unit of industrial frequency is Hertz HZ. China uses 50Hz, and some countries use 60Hz.

4. What is the role of variable frequency power supply

Variable frequency power supply can not only simulate and output the grid indicators of different countries, but also provide pure, reliable, low harmonic distortion, high stability of voltage and frequency sine wave power output for export electrical appliance manufacturers in design, development, production, testing and other applications. Variable frequency power supply is very close to the ideal AC power supply and can output the grid voltage and frequency of any country. The inverter is composed of AC-DC-AC (modulation wave) and other circuits. The standard name of the inverter should be variable frequency speed regulator. The waveform of its output voltage is a pulse square wave, and there are many harmonic components. The voltage and frequency change proportionally at the same time and cannot be adjusted separately, which does not meet the requirements of AC power supply.

The most advanced variable frequency power supply in the world today is a high-performance precision power supply designed with IGBT inverter output technology and advanced microprocessor control. It has overcurrent, short circuit, overvoltage, undervoltage, overload and other protection and alarm fault display functions to ensure the safety of electrical equipment and variable frequency power supply. It has the characteristics of strong load adaptability, good output waveform quality, good human-machine interface, simple operation, small size and light weight. The variable frequency power supply with sinusoidal wave output and adjustable output voltage and frequency provides the required AC power for electrical equipment.

5. Which is better, variable frequency power supply or industrial frequency power supply

5.1 Variable frequency is more energy-saving than industrial frequency.

Frequency conversion technology is a technology that adjusts the speed of the motor by adjusting the power supply frequency. Compared with the traditional industrial frequency fixed speed motor, the variable frequency motor can adjust the speed according to actual needs, thereby achieving more efficient energy utilization.

5.2 Variable frequency has advantages over industrial frequency in some aspects, and both have applicable scenarios and advantages and disadvantages.

Advantages of frequency conversion:

1. Energy saving: The frequency converter adjusts the speed by changing the operating frequency of the motor, which is more accurate than the power frequency operation and can reduce energy waste.

2. Low noise: Since frequency conversion technology can control the speed of the motor, in some application scenarios, the use of frequency conversion can significantly reduce noise.

3. Wide speed regulation range: Frequency conversion technology can achieve stepless speed regulation of the motor to meet the needs of more scenarios.

Features of power frequency:

1. Simple and easy to use: The power frequency is a fixed frequency operation with simple control. For equipment that does not require frequent speed regulation, it is more economical and practical to use the power frequency.

2. Good stability: The power frequency operation is relatively stable. For some equipment or systems that require stable operation, the power frequency is a good choice.

In general, frequency conversion and power frequency each have their own advantages and applicable scenarios. When choosing, you need to decide which method is more suitable according to specific needs and usage environment. With the advancement of science and technology and the deepening of application, frequency conversion technology may be more widely used and developed in the future.

Share our interesting knowledge and stories on social media