Monolithic DC-DC converters are an excellent choice for many high-volume applications due to the need to reduce cost and save space, but they cannot be used in designs that require electrical isolation between the power input and output. Medical devices are a good example. Often, board-mounted isolated power supplies are used instead, but these rely on transformers to achieve the required electrical isolation, which reduces efficiency and increases solution cost, size, and weight. Transformers also introduce instability to the DC-DC converter's performance and make large-scale automated assembly difficult. To address many of these challenges, designers can turn to isolated DC-DC converter modules that embed the transformer into the converter substrate.

This article explains when an isolated DC-DC converter is needed. It then introduces Murata Electronics example solutions and shows how they can be used to achieve isolation without the significant design trade-offs typically associated with transformer-based isolated DC-DC converters. The article concludes by showing how the converter's packaging meets the needs of high-level, automated surface-mount assembly and showing how isolated DC-DC converters can be designed into products to achieve minimal voltage and current ripple and reduce electromagnetic interference (EMI).

When to Use an Isolated Converter

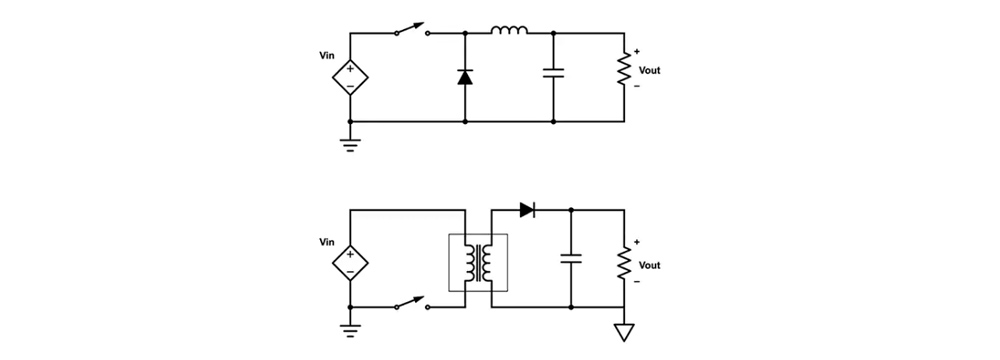

In a traditional DC-DC converter, a single regulator circuit allows current to flow directly from the input to the output. This reduces complexity, size, and cost. However, there are many applications that require galvanic isolation (hereafter referred to as “isolation”), where the input and output sides of a device need to be electrically separated. For example, safety purposes may require the use of an isolated DC-DC converter, where voltages and currents are transmitted separately between the input and output sides using a transformer (or in some cases, a coupled inductor), especially when the voltages connected to the input side are high enough to endanger human safety. Isolated DC-DC converters are also useful for breaking ground loops, separating noise-sensitive parts of a circuit from noise sources (Figure 1).

Another feature of isolated DC-DC converters is a floating output. While such converters do provide a fixed voltage between the output terminals, they do not have a defined or fixed voltage relative to the voltage level of the circuit they are isolating (i.e., they “float”). One option is to connect the floating output of an isolated DC-DC converter to a circuit node on the output side to fix its voltage, thereby causing the output to move or reverse relative to another point in the output side circuit. Since the input and output circuits are separate, the designer must ensure that both circuits have their own ground reference. The data sheet of a given DC-DC converter usually lists its isolation voltage, which is the maximum voltage that can be applied for a specified (short) time without current crossing the gap.

In addition, the data sheet also details the maximum working voltage that can be continuously withstood without violating the isolation. Isolation does come with some tradeoffs. First, isolated converters tend to be more expensive because the transformer (usually custom) is more expensive than the equivalent inductor (off the shelf) used in non-isolated converters. The higher the isolation capability required, the higher the cost. Second, isolated DC-DC converters tend to be larger than non-isolated converters; transformers are generally larger than equivalent inductors, and inductors tend to operate at higher switching frequencies, which can be further reduced in size compared to transformers. Third, the efficiency, regulation, and component-to-component performance repeatability of isolated DC-DC converters are often inferior to nonisolated converters.

The transformer causes efficiency losses compared to an inductor, and the isolation barrier prevents the output from being directly sensed and tightly controlled, thus preventing better regulation and transient performance. Due to their smaller size, nonisolated DC-DC converters can be placed closer to the load, reducing transmission line effects and further improving efficiency. In addition, because the transformer in an isolated converter is usually custom manufactured, no two devices will provide exactly the same output. Finally, the transformer also hinders efficient mass assembly processes. The form factor of an isolated DC-DC converter with a transformer makes it unsuitable for automated assembly, dictating that it must be hand-soldered to the PCB.

Isolated DC-DC Converter Selection

If a designer's application requires isolation for safety or other reasons, then the trade-offs described above must be considered. If you spend more time researching these components, you can find some newer solutions designed to minimize the impact of design trade-offs. For example, Murata recently introduced its NXE (Figure 2) and NXJ2 series of isolated DC-DC converters. These products are designed to address some of the traditional challenges posed by isolated DC-DC converters.

The NXE series provides up to 2 watts of power and offers 5 and 12 V input and 5, 12, and 15 V output options. Input and output currents vary with voltage, ranging from 542 milliamps (mA) input/400 mA output for the 5/5 V products to 205/133 mA for the 12/15 V products. The switching frequency for this product series is 100 to 130 kilohertz (kHz), depending on the model.

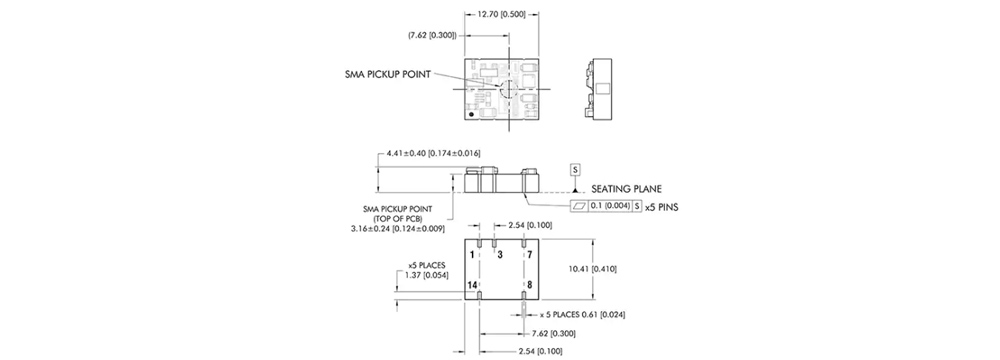

Similarly, the NXJ2 series is also a 2-watt design with 5, 12, and 24 V input and 5, 12, and 15 V output options. Input and output currents range from 550 mA in/400 mA out for the 5/5 V product to 105/133 mA for the 24/15 V product. Switching frequencies range from 95 to 140 kHz. Murata isolated DC-DC converters address automated manufacturing challenges by embedding the transformer into the substrate of the device. The transformer is constructed using alternating layers of FR4 (the glass-reinforced epoxy laminate typically used for printed circuit boards) and copper to form a winding around an embedded core. The embedded transformer structure is said to help dissipate heat and improve performance repeatability from part to part. The result is a flat (less than 4.5 mm) and compact (15.9 × 11.5 mm for the 5 V and 12 V versions, 16 × 14.5 mm for the 24 V version) package that fits on tape and reel and can be picked up by the vacuum nozzle of an automated placement machine (Figure 3).

The embedded transformer design achieves good electrical performance compared to other isolated designs. Isolated DC-DC converters typically have efficiencies ranging from 55% to 85% when operating at full load. The NXE series and NXJ2 series have efficiencies of approximately 72% for 5 V output at 100% load, rising to 76% for 15 V output and 78% for 24 V output.

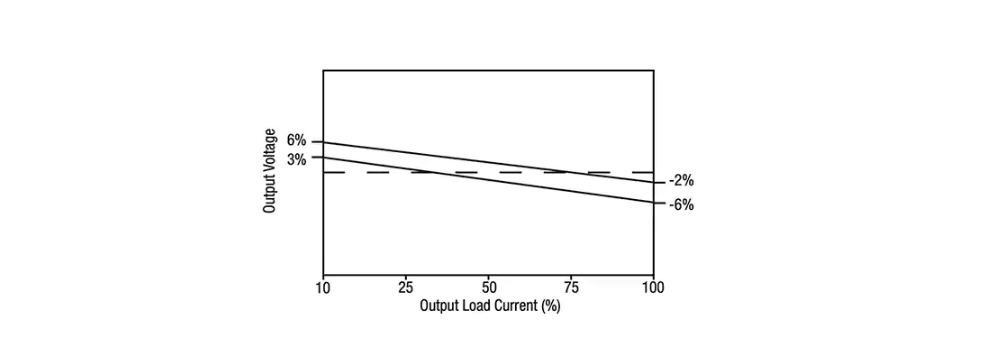

Isolated DC-DC converters generally lack the precise regulation typical of nonisolated products because they have no electrical feedback loop between output and input. For the NXE series, line regulation is 1.15%/%, with load regulation ranging from 7% to 11%. The NXJ2 has line regulation of 1 %/% for 24 V input and 1.1 %/% for all other input types. The accuracy of the voltage set point depends on the output load current and the NXE or NXJ2 device selected. For example, the NXE2S1215MC 12 V input/15 V output solution has a -2 to -6% change from set point at full output load current (Figure 4).

Understanding the Specifications

Electrical separation of input and output is often a regulatory requirement, so engineers must understand the regulatory requirements for a particular design. This can be difficult because the information can be confusing. For example, regulatory standards specify isolation requirements for components and isolation requirements for end products separately—and each requirement is different. For example, a component specification sheet may state that the device can withstand isolation test voltages of 2.5 to 5 kilovolts ac and meets product standard IEC 60950-1. But more important to the designer is the working voltage of the isolator, such as 150 to 600 volts ac, and meets component standard IEC 60747-5-5. Also pay attention to the terminology describing the isolation level. "Basic" is a single layer of isolation, "double" is two layers of isolation, and "reinforced" is a single layer of isolation equivalent to a double layer.

The standard assumes that a single layer of isolation can fail once, so products with a second isolation layer can still provide protection. Importantly, when a component is defined as “basic” in a component standard, it is classified as insufficient for safety protection. Another important aspect of a component’s isolation performance is its clearance and creepage distances. Clearance is the narrowest air distance between two component circuits, while creepage is the shortest distance that current can travel across a surface.

The best way for a designer to determine the performance of an isolator is to verify that the isolator is certified by VDE and Underwriters Laboratory (UL) and obtain a copy of the actual certificate from the isolator manufacturer. In the NXE and NXJ2 series, FR4 provides the isolation barrier for the converter primary and secondary windings, and each component was tested at 3 kV DC for one second and a sample qualification test at 3 kV DC for one minute. The insulation resistance was measured at 10 gigaohms (GΩ) at a 1 kV DC test voltage. Both the NXE and NXJ2 series are UL certified to ANSI/AAMI ES60601-1 and provide a single MOOP (Means of Operator Protection) between the primary and secondary coils based on a maximum working voltage of 250 V rms. UL also confirms that these DC-DC converters meet the UL 60950 standard for reinforced isolation with a working voltage of 125 V rms. The devices have a creepage distance of 2.5 mm and a clearance of 2 mm.

Reduced Output Ripple and EMC

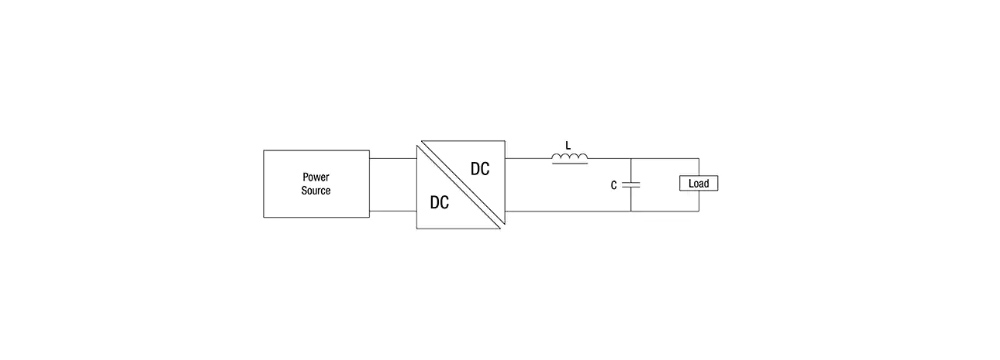

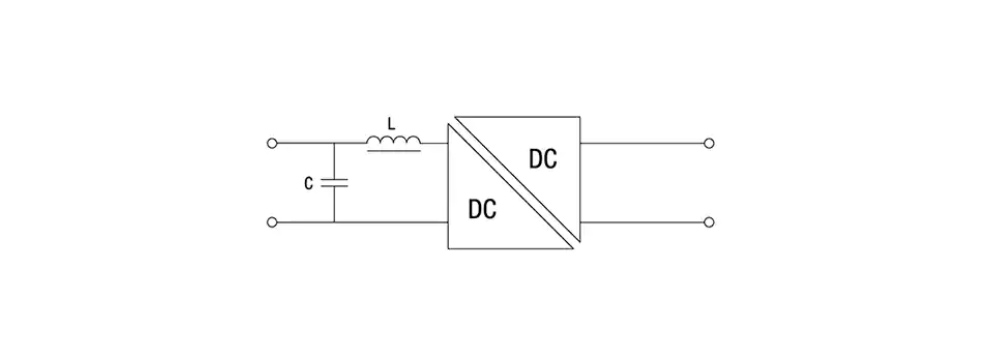

Switching voltage converters always face design challenges related to the voltage and current ripple generated by the switching elements. Isolated DC-DC converters are no exception. Without output filtering circuitry, the typical output ripple of the NXE DC-DC converters is about 55 millivolts (mV) peak-to-peak (p-p) and a maximum of 85 mVp-p. The corresponding values for the NXJ2 series are 70 mVp-p and 170 mVp-p. While these values are acceptable for many applications, others require a more stable output. The output filter circuit shown in Figure 5 can be used to significantly reduce the output current and voltage ripple. The values of the inductor (L) and capacitor (C) vary depending on the input and output voltages of the DC-DC converter; for example, Murata's NXE2S1205MC (12 volt input/5 volt output) product requires a 22 microhenry (μH) inductor and a 10 microfarad (μF) capacitor. The output filter circuit works to reduce the output voltage and current ripple to a maximum of 5 mVp-p.

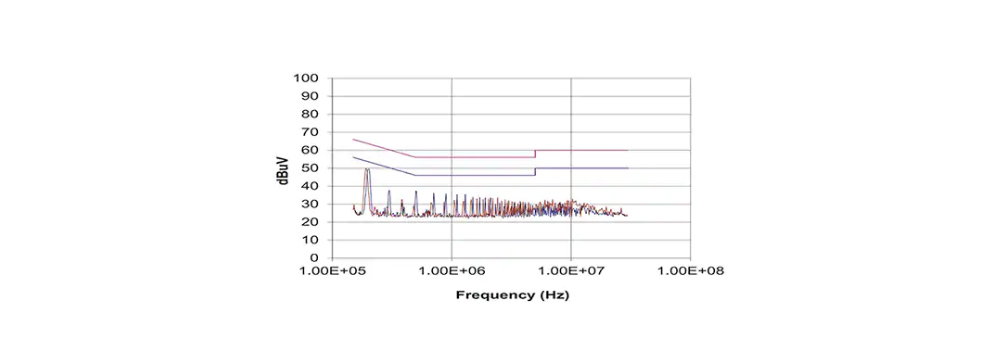

For best results, the capacitor's equivalent series resistance (ESR) should be as low as possible and the voltage rating should be at least twice the rated output voltage of the isolated DC-DC converter. For the inductor, its rated current should be no less than the output current of the DC-DC converter. At rated current, the DC resistance of the inductor should be such that the voltage drop across the inductor is less than 2% of the rated voltage of the DC-DC converter. As shown in Figure 6, input filtering circuits can be added to the NXE and NXJ2 series to suppress EMI. Again, the values of L and C depend on the input and output voltages of the DC-DC converter; for example, Murata's NXE2S1215MC (12V input/15V output) product would require a 22 μH inductor and a 3.3 μF capacitor.

As shown in Figure 7, the filtering effect enables Murata's isolated DC-DC converters to meet the EN 55022 Curve B quasi-peak EMC limits. Devices that radiate EMI must be below these limits to meet the EU's 2014 EMC Directive.

Conclusion

Isolated DC-DC converters play an important role when regulations or safety considerations require electrical isolation of input and output voltages. But using transformers for isolation can introduce design tradeoffs—particularly cost, size, performance variability, and assembly challenges. Engineers need to be aware of these tradeoffs and design their products accordingly. For example, isolated DC-DC converters typically lack the feedback loop that allows for the precise regulation of nonisolated products, so their output voltage can vary more with load relative to the set point than nonisolated products. As described in this article, instead of using expensive and bulky board-mount transformers, there are DC-DC solutions that use alternating layers of FR4 and copper to build a transformer embedded in the converter substrate. As a result, such devices are lower cost, more compact, exhibit better component-to-component electrical performance repeatability, and can be picked up by automatic chip placement machines. These isolated DC-DC converters also meet standards for high-voltage isolation and insulation testing.

Share our interesting knowledge and stories on social media