In the world of electronic devices, heat dissipation has always been a focal point for both engineers and users. Whether it's smartphones, laptops, or smart home devices, overheating can lead to performance degradation, device damage, and even safety hazards. Behind this issue, the Step-Down Converter which a key component often emerges as the primary culprit. Today, let's delve into why your electronic devices are overheating and explore the common thermal design pitfalls associated with step-down converters.

I. Step-Down Converters: The "Energy Transformers" in Electronic Devices

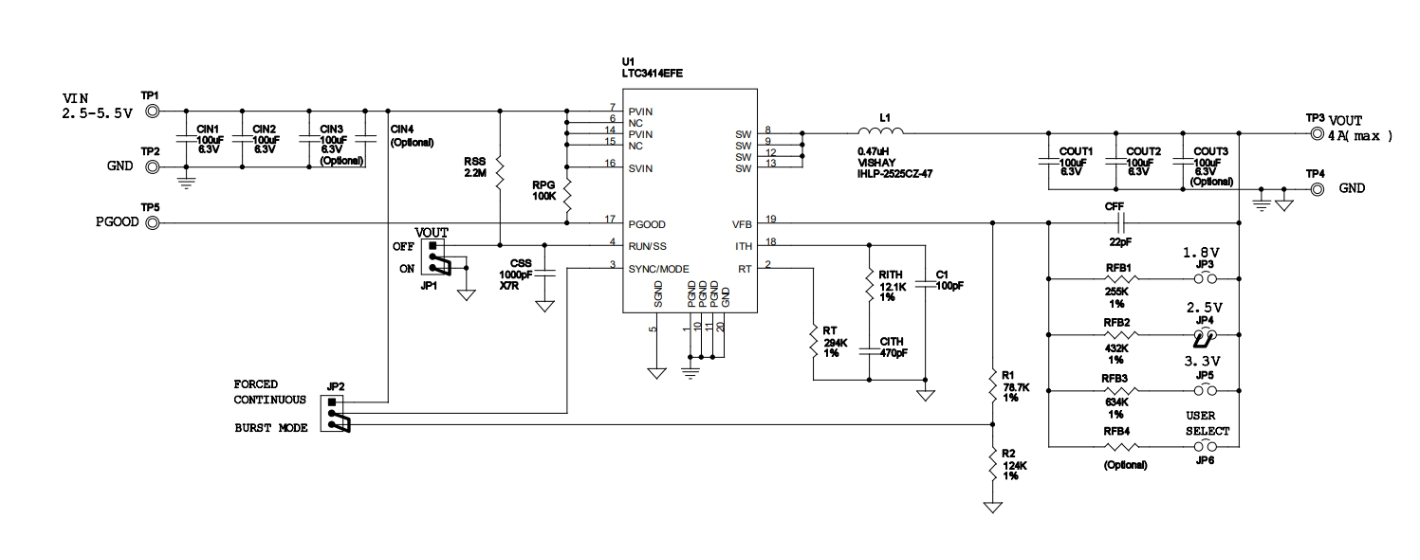

In electronic devices, the step-down converter is a common power management component whose main function is to convert high input voltage into the lower voltage required by the device. For example, it converts a 12V power supply voltage to 3.3V for use by microcontrollers or other low-voltage devices. Although this conversion process is relatively efficient, it still generates some energy losses, which are primarily dissipated in the form of heat.

Under normal circumstances, the heat generated by a step-down converter can be effectively managed. However, when thermal design issues arise, heat accumulates, causing the device temperature to rise. This not only affects the device's performance but can also shorten its lifespan.

II. Thermal Design Pitfalls: Why Your Electronic Devices Overheat

(i) Insufficient Heat Dissipation Area

The heat dissipation area is a crucial factor affecting thermal performance. Many designers, when selecting a step-down converter, often focus solely on its conversion efficiency while neglecting the importance of the heat dissipation area. For example, in small-form-factor electronic product designs aimed at saving space, smaller step-down converters may be chosen, yet these converters often have limited heat dissipation areas.

Case Example: A certain smartphone, in pursuit of a slim design, opted for a smaller step-down converter. Although the conversion efficiency exceeded 90%, the limited heat dissipation area caused the converter's temperature to soar under high-load operation, leading to severe device overheating and even automatic shutdowns.

(ii) Improper Selection of Heat Dissipation Materials

The choice of heat dissipation materials also impacts thermal performance. Some designers may opt for cheaper materials, such as ordinary plastics or aluminum, which have poor thermal conductivity and cannot effectively dissipate heat.

Case Example: A certain smartwatch, in an effort to reduce costs, used a plastic casing. Although plastic casings offer good insulation properties, their poor thermal conductivity prevented the heat generated by the step-down converter from being dissipated in a timely manner, causing the watch to overheat significantly after a period of use.

(iii) Unreasonable Heat Dissipation Path Design

The design of the heat dissipation path is equally important. If the path is poorly designed, heat cannot be efficiently conducted to the external environment, leading to heat accumulation. For example, some electronic products may place the step-down converter in a corner inside the device, surrounded by other components, leaving insufficient space for heat dissipation.

Case Example: A certain smart home gateway placed the step-down converter in an internal corner, surrounded by other components. Although a heat sink was used, the poor heat dissipation path prevented the heat from being effectively conducted to the casing, resulting in severe device overheating after prolonged operation.

(iv) Ignoring the Impact of Ambient Temperature

Ambient temperature also significantly affects thermal performance. In high-temperature environments, the thermal conductivity of heat dissipation materials decreases, and the effectiveness of heat dissipation deteriorates. Some designers may overlook the impact of ambient temperature during the design phase, leading to poor heat dissipation in high-temperature conditions.

Case Example: A certain outdoor smart device, without considering the thermal requirements for high-temperature environments during design, still experienced a rapid temperature rise under high-temperature conditions despite using an efficient step-down converter and a good thermal design, resulting in performance degradation.

III. How to Avoid Thermal Design Pitfalls

(i) Reasonably Select Heat Dissipation Area

When choosing a step-down converter, the heat dissipation area should be selected based on the device's power requirements and operating environment. For high-power or high-load devices, step-down converters with larger heat dissipation areas should be chosen, or multiple converters can be used in parallel to distribute the heat.

(ii) Choose Suitable Heat Dissipation Materials

The selection of heat dissipation materials should be based on a comprehensive consideration of the device's thermal requirements and cost budget. For devices with high thermal requirements, materials with better thermal conductivity, such as copper or aluminum alloy, can be chosen. Additionally, auxiliary thermal materials like thermal paste or thermal pads can be used to enhance thermal performance.

(iii) Optimize Heat Dissipation Path

When designing the heat dissipation path, it is essential to ensure that heat can be efficiently conducted to the external environment. This can be achieved by increasing heat dissipation channels and optimizing component layout to improve the efficiency of the heat dissipation path. For example, placing the step-down converter near the device's ventilation port or using heat pipe technology to quickly conduct heat to the casing.

(iv) Consider the Impact of Ambient Temperature

When designing a thermal solution, the impact of ambient temperature should be fully considered. For devices intended for use in high-temperature environments, higher-performance heat dissipation materials and technologies should be employed to ensure normal operation under high-temperature conditions.

IV. Conclusion

The thermal design of step-down converters is an indispensable and crucial aspect of electronic device design. By reasonably selecting the heat dissipation area, choosing suitable heat dissipation materials, optimizing the heat dissipation path, and considering the impact of ambient temperature, common thermal design pitfalls can be effectively avoided. This enhances the thermal performance and lifespan of electronic devices. It is hoped that the insights shared in this article will help you better understand and address electronic device overheating issues, allowing your devices to operate efficiently while maintaining "coolness."