In the complex system of electric vehicles, the DC/DC converter is small but plays a pivotal role. It is like the "energy hub" of electric vehicles, silently maintaining the stable operation of various systems. Are you curious about how DC/DC works? What are the key impacts on the performance of electric vehicles? Next, we will start a comprehensive summary of DC/DC knowledge of electric vehicles for you.

With the rapid development of new energy electric vehicle technology, the importance of DC-DC power supplies as key components in these vehicles has become increasingly prominent. These power supplies are not only responsible for managing the power supply of the vehicle's main power battery, but also optimizing the energy efficiency of the entire vehicle and ensuring the stable operation of various electronic systems.

1. What is a DC/DC converter?

Overview of DC/DC converters

All EV devices rely on electricity to work. Driving motors, etc. rely on the power of large/high-voltage lithium-ion batteries to work, and a large number of other on-board devices (ECU, cameras, lights, etc.) rely on the power of low-voltage lead-acid batteries to work. Lead-acid batteries will run out of power if they are not charged, so they need to be charged from lithium-ion batteries. Among them, the device that converts high-voltage DC power into low-voltage DC power is the DC/DC converter. By converting to low voltage, various on-board devices of EV can operate at an appropriate voltage.

2. The difference between high voltage and low voltage

2.1 The purpose of high voltage

In order to operate the driving motor, high voltage is required. Because the motor requires high power, if it is tried to operate at a low voltage, a large current will be generated, which will increase the loss in the circuit and deteriorate the conversion efficiency. In order to improve efficiency, it is necessary to use a high voltage (400V or more) to suppress the current.

2.2 The purpose of low voltage

Low voltage is used for devices other than those related to the driving motor (various devices in the car and headlights, etc.). In addition, even for high-voltage devices, their internal control circuits operate at low voltage. Therefore, a DC/DC converter that converts from high voltage to low voltage is indispensable.

2.3 Why low voltage is 12V

Early cars started the engine manually, and later a mechanism that used a starter motor to start was developed. In order to drive this starter motor, a lead-acid battery was installed. Currently, a 12V battery pack composed of 6 lead-acid battery cells (each battery cell is about 2.1V) is used in cars. However, a large motor is used for the starter motor of the engine on a truck, so a 24V battery pack (12V battery × 2) is usually used.

3. Circuit structure of DC/DC converter

Overall structure

- Voltage detection (input side): Measure the input voltage from the lithium-ion battery - Noise filter (input side): Remove noise using capacitors and coils - Voltage conversion circuit: Convert voltage by switching through insulation transformers and FETs - Noise filter (output side): Remove noise using capacitors and coils - Voltage detection (output side): Measure output voltage - Control circuit: Control conversion circuit, etc. - DC/DC converter: Supply power to the control circuit - Communication circuit: Communication circuit with the outside

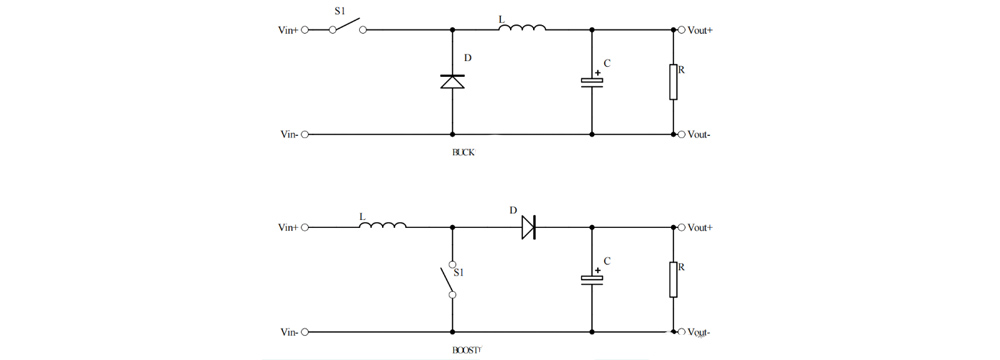

DC-DC power supply, also called DC-DC converter, is mainly used to convert one DC voltage into another DC voltage. They adjust the output voltage through electronic switching elements such as transistors and energy storage elements such as inductors and capacitors to achieve high efficiency and stable voltage conversion.

These power supplies play a key role in controlling the duty cycle of the electronic switch to accurately adjust the output voltage to meet the needs of different loads.

Conversion efficiency, that is, the ratio of input power to output power, is a key indicator to measure the performance of DC-DC power supplies, which directly affects the energy utilization and heat loss of the system.

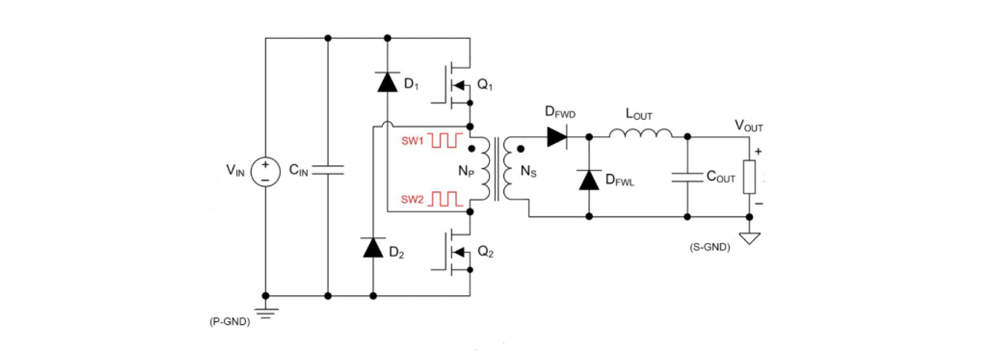

DC-DC power supplies are divided into two categories: isolated and non-isolated. Isolated converters achieve electrical isolation between input and output through transformers, provide higher safety, and are suitable for applications with high electrical safety requirements. Non-isolated converters are more compact and cost-effective, and are suitable for most low-power applications.

4. Common isolated DC-DC

In addition, switching converters control the output voltage by adjusting the operating frequency and duty cycle of the switching elements, which is suitable for a variety of applications, while linear converters provide smooth and stable voltage output, which is suitable for scenarios sensitive to voltage stability and noise.

In new energy electric vehicles, DC-DC converters play a vital role in the battery management system. These converters not only perform effective power conversion and allocation between the battery and the various electronic systems of the vehicle, but also support voltage matching during battery charging.

For example, the high voltage of power batteries (such as lithium-ion batteries) needs to be reduced to the charging requirements of lead-acid batteries by DC-DC converters. In addition, in the drive system, the DC-DC converter ensures that the power supply from the high-voltage main battery to the motor is stable and efficient. For auxiliary systems such as air conditioning, lighting, etc., the converter provides the necessary power regulation and distribution.

Challenges faced by DC-DC conversion technology include thermal management issues, improving efficiency and reducing volume, and challenges of high-voltage and high-frequency applications. Strategies to address these challenges include optimizing heat sink design, using high-efficiency switching elements, applying high-frequency switching technology, and using high-voltage components and optimized isolation technology.

With the application of new materials and technologies, such as gallium nitride and silicon carbide semiconductor materials, the energy conversion efficiency and volume of DC-DC converters are being significantly improved. This is crucial to promote the development of the electric vehicle industry.

In the field of new energy electric vehicles, the future of DC-DC power supplies is closely linked to innovation and technological progress. They not only improve the efficiency of electric energy use, but also enhance the performance and reliability of vehicles. Therefore, a deep understanding of DC-DC power supplies is essential for the design and optimization of electric vehicles.

Share our interesting knowledge and stories on social media