In the development of high-power switching power supplies at the kilowatt level and above, the quality of heat dissipation design directly determines the power density, long-term reliability, and lifespan of the entire system. As power levels continue to increase, if heat losses generated by power devices such as IGBTs and fast recovery diodes cannot be dissipated in time, it will lead to a sharp rise in chip junction temperature, causing thermal failure. Therefore, thermal management has become a core aspect as important as electrical design. Currently, forced air cooling and liquid cooling are two mainstream technical routes, which differ significantly in principle, efficiency, and engineering implementation.

I. Design Considerations and Technical Limitations of Forced Air Cooling Systems

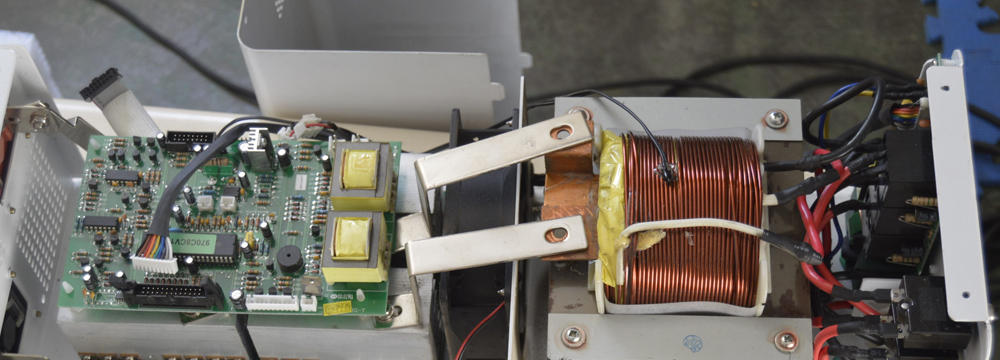

Forced air cooling relies on air as the cooling medium. Its heat transfer path is: device die → casing → thermally conductive insulating pad → heat sink substrate → heat sink fins → flowing air. Each link in this path has thermal resistance, and the total thermal resistance after series connection determines the final heat dissipation effect.

The core of air cooling design lies in the optimization of the heat sink and airflow. The shape, spacing, and height of the heat sink fins need to achieve a balance between increasing the heat dissipation area and controlling airflow resistance. Excessively dense fins lead to excessive air resistance. Even with a high-volume fan, the actual airflow velocity between the fins decreases, resulting in a reduction in overall cooling efficiency.

Airflow design is widely considered the "soul" of an air-cooled system. Improper airflow organization can cause eddies and localized dead zones, preventing effective cooling of some heat-generating components. Computational fluid dynamics simulation has become a standard design process for optimizing airflow and avoiding hotspots. Furthermore, fan selection must be based on the system's air resistance characteristics; matching the air pressure-airflow curve with the system impedance curve is crucial.

Air cooling is simple in structure, low in cost, and easy to maintain, but its heat dissipation capacity is limited by the low specific heat and low thermal conductivity of air. When the power density of the power supply exceeds approximately 0.5 watts per cubic centimeter, or in high-temperature environments, the size and noise of the air-cooled system increase dramatically, mortgaging its cooling efficiency.

II. Working Principle and Engineering Challenges of Liquid Cooling Systems

Liquid cooling technology replaces the cooling medium with a liquid (commonly deionized water or water-glycol solution), utilizing the liquid's significantly higher thermal conductivity and specific heat capacity than air to achieve efficient heat transfer. The heat path is: device die → casing → thermally conductive pad → cold plate → circulating coolant → external heat exchanger → ambient air. The key advantage of this path is that it decouples the cooling of the internal heat-generating element from the final release of heat to the environment into two relatively independent stages.

The core component of a liquid cooling system is the cold plate. The heating element is directly mounted on the surface of the cold plate, and its precisely machined internal flow channels determine the heat exchange efficiency. From simple serpentine flow channels to advanced microchannel structures, the goal of flow channel design is to maximize the heat exchange surface area and enhance fluid turbulence. While microchannel cold plates can greatly improve heat exchange efficiency, they also pose significant challenges to manufacturing processes and sealing reliability.

A complete liquid cooling system is a complex subsystem, including the cold plate, circulating pump, liquid storage tank, outdoor radiator, and connecting pipes and sealing interfaces. The system must ensure absolutely leak-free operation over long periods, thus placing extremely high demands on the insulation and corrosion resistance of the coolant, as well as the sealing processes of all interfaces. This complexity leads to the high initial cost of liquid cooling systems and the need for specialized maintenance.

III. Analysis of Applicable Scenarios for the Two Technical Approaches

In terms of heat dissipation capacity, liquid cooling exhibits a clear advantage. It can handle localized high heat flux densities exceeding several hundred watts per square centimeter, while air cooling is typically limited to tens of watts. This allows liquid-cooled power supplies to achieve a power density three to five times that of air-cooled products of the same power, enabling miniaturization and weight reduction of equipment.

Regarding noise control, the high-speed fans of air-cooled systems are the main noise source, with sound pressure levels often exceeding 65 decibels. The noise of liquid-cooled systems mainly originates from the pump and the low-speed fans of the external heat exchanger, and sound insulation measures are easily implemented, keeping the overall noise level below 50 decibels, making it suitable for environments requiring quiet operation, such as laboratories and medical facilities.

In terms of environmental adaptability, air-cooled systems are easily affected by the working environment. Dust, lint, salt spray, etc., can clog the heat dissipation channels, leading to performance degradation. Liquid cooling systems, because their core heat-generating components are sealed on a cold plate and isolated from the harsh external environment, are particularly suitable for demanding industrial applications such as metallurgy, chemical engineering, and marine industries.

Regarding cost and maintenance, air-cooled systems have an advantage due to their lower component costs and simpler maintenance operations such as dust cleaning and fan replacement. Liquid cooling systems require a larger initial investment and specialized personnel for maintenance, but their high reliability reduces downtime losses in continuous production, making them potentially more economical from a total life-cycle cost perspective.

Share our interesting knowledge and stories on social media