With the rapid development of generative AI technologies such as GPT and Deepseek, the AI industry is rapidly moving towards a new stage of technological breakthroughs. Global tech giants are increasing their investment in large-scale data centers to meet the ever-growing computing power demands. This has not only driven the expansion of data center scale but also spurred the upgrading and innovation of the entire industry chain.In May 2025, NVIDIA announced that it would lead the transition of rack power supplies from 54V DC to 800V High Voltage Direct Current (HVDC) starting in 2027, attracting significant industry attention. This article will trace the evolution of data center power supply architecture and discuss the impact of the 800V HVDC architecture on upstream components such as power products.

Data Center Power Supply Architecture

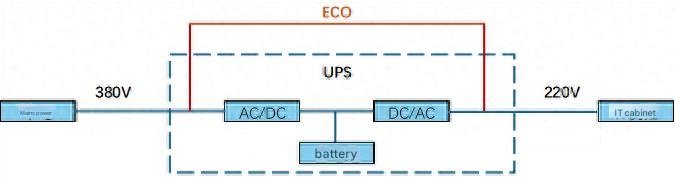

Development History Early data center power distribution architectures mostly adopted traditional UPS (Uninterruptible Power Supply) solutions. The main structure consisted of rectified AC-DC, inverter DC-AC, and static bypass (see ECO in the diagram below, i.e., power supply through bypass). After the mains power is introduced, it undergoes primary distribution via a transformer, and then secondary distribution via a UPS. Under normal circumstances, the input AC power, after rectification and inversion, supplies power to the load and simultaneously float-charges the batteries connected to the DC bus. When the input AC power is interrupted, the batteries automatically switch to discharge mode, continuing to supply power to the load through the inverter, thus ensuring that the load's power supply is uninterrupted. Inside the rack, the universal redundant power supply for each server blade rectifies and steps down the AC power to 12 volts, providing input voltage to the server motherboard.

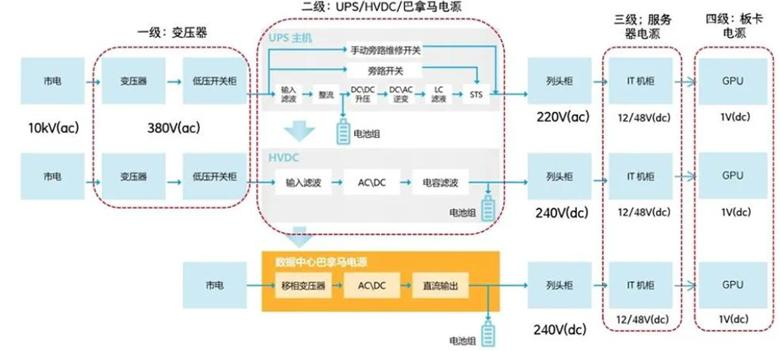

To ensure reliability, traditional data centers often use power supply architectures such as N+1, 2N, DR, and RR. However, these architectures have many redundant links, are complex, and have low efficiency. For example, a typical 2N redundant UPS system has an overall efficiency of only about 93%, meaning that supporting 1MW of AI computing power requires an additional 70kW of power. For decades, this architecture has been the industry standard for data center power supply, and a large portion of systems still use this configuration today. In this architecture, a typical server rack supports a power range of 10KW to 15KW. However, the rise of giant cloud data centers has driven continuous increases in power levels, giving rise to a new generation of power supply architectures. In 2013, at the Green Internet Data Center Summit, Google showcased its then-latest 48V rack and UPS. The server motherboard directly supports 48V and directly steps down the voltage from 48V to the CPU's POL (Point of Load), reducing the 12V intermediate conversion stage, resulting in higher efficiency and lower cost. This power supply architecture achieves an extremely streamlined architecture from the power grid to 48V and then to the CPU, eliminating the need for a data center-level UPS and the secondary conversion from 48V to 12V at the rack level, while implementing a single-stage conversion from 48V to the CPU at the server motherboard level. It differs from traditional UPS solutions in several ways: the server power supply voltage is increased to 48V, and the power supply is integrated into the power rack, also known as an "open rack" power supply, which also integrates local backup battery units within the rack. In 2016, Google announced its collaboration with OCP at the OCP Summit, contributing its 48V rack architecture and specifications to the OCP alliance.

Figure: Google's 48V rack layout, Source: OCP 2016 Summit

Compared to traditional 12V server architecture, this reduces energy consumption by more than 30%, significantly lowering energy consumption in global cloud data centers. It utilizes customized 48V power supply POL servers, with all server power supplied from the 48V busbar at the rear of the rack, supporting a single rack power density of over 30KW. In 2019, at the Data Center Standards Summit, Alibaba, together with Delta and Zhongheng Electric, launched a new internet data center power supply solution—the Panama Power Supply. The Panama Power Supply revolutionizes traditional IDC power supply architecture, innovatively integrating circuit and magnetic circuits to directly convert from medium-voltage 10KV AC to 240V DC (or 336V DC), replacing numerous intermediate devices between the medium-voltage input and DC output in traditional architectures, allowing for one-step power transmission that is more efficient and reliable.

Figure: Alibaba Data Center Panama Power Supply, Source: Guoxin Securities Research Institute

The Panama power supply boasts a power module efficiency of up to 98.5%, a simple architecture, and high reliability, ensuring uninterrupted operation of the power supply system for five years. Compared to traditional data center power supply solutions, it reduces equipment and engineering construction by 40% and floor space by 50%. It's worth noting that because the Panama power supply model is a customized solution rather than an industry standard, it has not yet been widely deployed outside of Alibaba. However, with the rapid increase in power demands of AI data centers, single-rack energy consumption is climbing from 100kW to over 1MW, highlighting the limitations of the 48V/54V DC power supply mode:

Space Constraints: Taking the NVIDIA GB300 system as an example, eight power supply racks occupy 64U rack space, severely compressing the space for computing card installation. In contrast, an 800V system can power 576 Rubin Ultra GPUs within a single Kyber rack, improving space utilization by over 80%.

Copper Cable Weight: A 1MW rack using 54V power requires 200kg of copper cable. Expanding to a 1GW data center, this would amount to 500,000 tons of copper cable, making it unsustainable in terms of both cost and weight. An 800V architecture can reduce copper cable usage by over 70%.

Efficiency Loss: 54V systems require multiple AC/DC conversions, resulting in low efficiency and numerous points of failure. The 800V solution directly converts the 8kV grid input to 800V DC using an industrial-grade rectifier, reducing intermediate steps and improving end-to-end energy efficiency by 5%, while also reducing heat dissipation pressure.

In May 2025, NVIDIA announced that starting in 2027, it would spearhead the transition of data center rack power supplies from traditional 54V DC to 800V high-voltage DC (HVDC) to support next-generation AI data centers with single-rack power exceeding 1MW.

Figure: Comparison of 48V and 800V architectures for data centers. Source: Navitas Semiconductor

Compared to existing 48V/54V distributed power supply solutions, NVIDIA's 800V HVDC system differs most significantly in that it uses a solid-state transformer (SST) instead of a traditional power frequency transformer, achieving a 13.8kV AC to 800V DC conversion. Then, a high-voltage DC-DC converter replaces the server power supply PSU, eliminating most intermediate conversion steps and minimizing power loss and copper usage. This results in a 5% improvement in system energy efficiency while reducing the total cost of ownership by 30%. From the above development history, data center power supply solutions are generally evolving towards DC, high voltage, and high density.

What is the impact of the 800V power supply architecture on upstream components?

The most direct impact of the 800V HV DC power supply architecture is driving the upgrade of power devices towards higher voltage and higher frequency. In the centralized rectification stage, especially in the critical solid-state transformer (SST), SiC MOSFETs with withstand voltage ratings of 2300V to 6500V or even higher are required. Compared to traditional silicon-based IGBTs, SiC devices can reduce switching losses by an order of magnitude under high-voltage, high-frequency conditions, laying a solid foundation for achieving an end-to-end efficiency improvement of approximately 5% across the entire power supply chain. In the rack-mounted DC/DC conversion stage, to achieve higher power density, the switching frequency needs to move towards the megahertz (MHz) level. GaN devices, with their excellent fast switching characteristics, become the ideal choice for this scenario. For example, under 800V input conditions, their drive and switching losses per half-wave switching cycle are significantly lower than those of SiC solutions. This also means that third-generation semiconductors, represented by SiC and GaN, have transitioned from alternatives to inevitable choices, squeezing the market space of traditional silicon-based superjunction MOSFETs and IGBTs. Simultaneously, the implementation of 800V HVDC power supply architecture not only tests the performance of the devices themselves but also presents new challenges to the supporting technology chain. The introduction of medium- and high-voltage SiC devices (such as those above 3300V) brings challenges in signal isolation. According to safety standards, the maximum instantaneous withstand voltage of isolation chips is typically required to be 3-5 times that of switching devices. This means that the safe withstand voltage of isolation chips with a voltage range of 3300V-6500V needs to be above 10kV, and the isolation voltage of a 10kV SiC MOSFET gate driver needs to exceed 20kV. Furthermore, the conduction dv/dt of a 10kV SiC MOSFET can reach 100V/ns. Therefore, isolation chips urgently need to improve their common-mode transient immunity (CMTI) performance. Traditional optocoupler, magnetic coupling, or capacitive isolation technologies cannot simultaneously meet the requirements in terms of withstand voltage and response speed, thus necessitating the development of next-generation isolation solutions. Against this backdrop, the market anticipates that the transformation of AI data center power supply architecture will reshape the market landscape of related industry chains, creating new growth opportunities for power semiconductor companies that have already deployed SiC/GaN technology (such as Infineon, ON Semiconductor, Navitas Semiconductor, and Innoscience), as well as suppliers in power management, magnetic components, and liquid cooling, thereby driving the formation of a new industrial ecosystem from semiconductor materials and device manufacturing to system integration.

In conclusion, the evolution of data center power supply architecture from traditional UPS to 48V DC, and then to 800V HVDC, is essentially a technological evolution in pursuit of ultimate efficiency and power density. The 800V HV DC power supply architecture is not merely an increase in voltage level, but a complete reshaping of the "power heart" of the data center.

Share our interesting knowledge and stories on social media