In modern electronic systems, more than 80% of power management tasks require voltage conversion. From the fast-charging chips in smartphones to the power supply modules in data center servers, from the drive systems of electric vehicles to the MPPT controllers in photovoltaic inverters, DC-DC converters play the crucial role of energy "translators"—efficiently converting electrical energy from one DC voltage form to another while ensuring the precision and stability of energy transfer.

Understanding how DC-DC converters work is not just a professional requirement for power engineers; it is a fundamental skill for all electronic system designers to optimize product performance and enhance reliability.

1.Core Operating Principles—The Essence of Energy Conversion

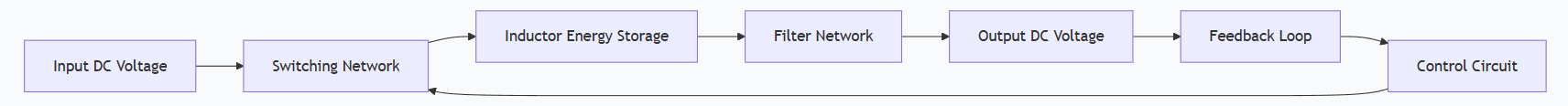

Fundamental Principle: The "Temporary Storage and Release" of Energy

All switching-mode DC-DC converters are based on one core principle: achieving voltage transformation by rapidly switching an inductor to control its energy storage and release.

The operating cycle consists of two phases:

Charging Phase: Switch is ON, inductor stores energy, current increases linearly.

Discharging Phase: Switch is OFF, inductor releases energy to the load.

The output voltage is determined by the duty cycle (D): Vout = D × Vin (buck) or Vout = Vin / (1-D) (boost).

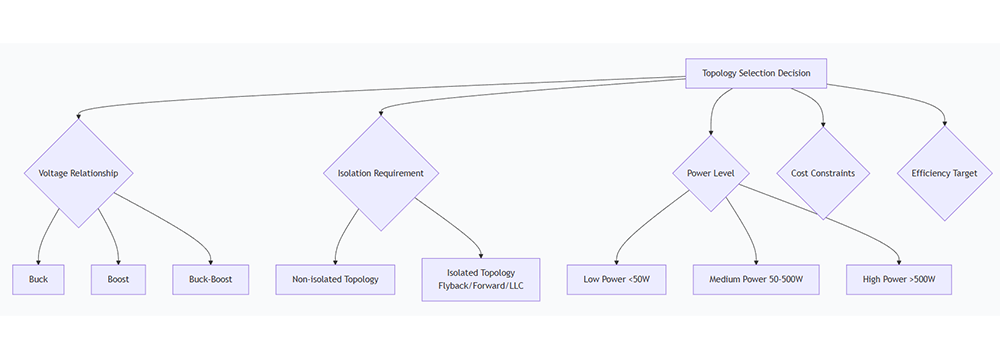

2.Engineering Decision Matrix for Topology Selection

2.1 Selection Criteria: Five Key Dimensions

2.2 Matching Typical Application Scenarios

2.2 Matching Typical Application Scenarios

Scenario 1: Automotive Infotainment System Power Supply

Requirements: 12V battery → 5V/3.3V, efficiency >92%, low cost

Selection: Synchronous Buck Converter

Reason: High efficiency, low cost, controllable EMI

Scenario 2: Isolated Power for Industrial Sensors

Requirements: 24V industrial bus → 5V isolated, safe for explosive environments

Selection: Flyback Converter

Reason: Achieves electrical isolation, moderate cost, suitable power level

Scenario 3: Server VRM in Data Centers

Requirements: 48V → 1.8V, current >100A, ultra-fast transient response

Selection: Multiphase Buck Converter

Reason: Distributes current stress, optimizes thermal management, improves response speed

3.Three-Level Engineering Practice for Efficiency Optimization

3.1 Device-Level Optimization: From Passive to Active

Evolution of Switching Devices:

When you look at a Si MOSFET you will see that the Rdson gets bigger when the voltage gets higher. This means that the resistance of the Si MOSFET, which is called Rdson is not the same, at every voltage level. It actually increases with voltage. So the Rdson of a Si MOSFET is affected by the voltage.

Practical Case Comparison:

300W Boost Converter, Input 24V → Output 48V.

Traditional Si MOSFET: 93% efficiency, switching frequency 150kHz.

GaN Solution: 96.5% efficiency, switching frequency 500kHz, 40% smaller volume.

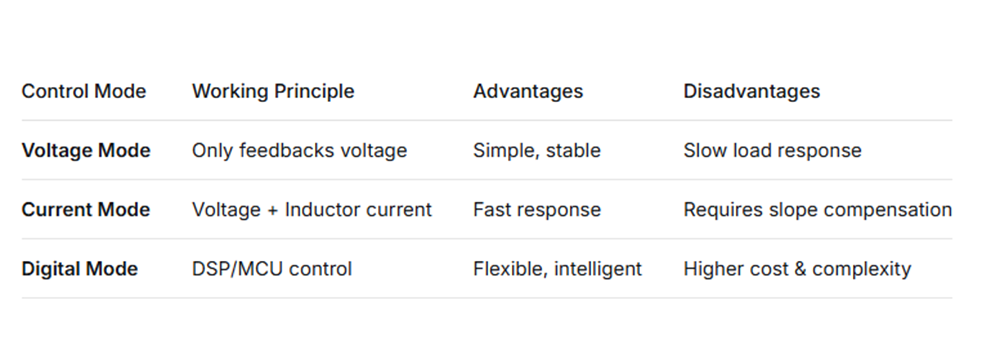

3.2 Control Strategy Optimization: From Analog to Digital

Evolution of Three Major Control Modes

Practical Advantages of Digital Control

The Adaptive Compensation feature helps to adjust the compensation parameters. This adjustment is based on the operating point of the system. So the Adaptive Compensation makes these changes, to the compensation parameters to make sure everything works properly at the operating point of the Adaptive Compensation system.

Multi-Mode Operation: Enters pulse-skipping mode at light loads.

Fault Logging: Stores abnormal data for diagnostics.

3.3 System-Level Optimization: Beyond Single-Point Efficiency

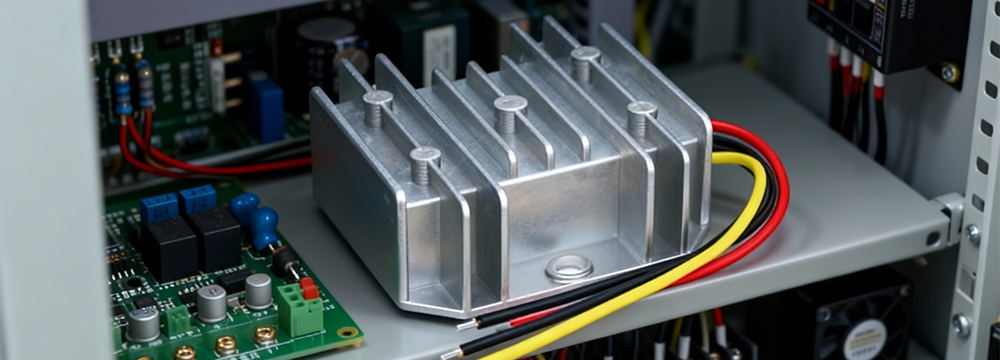

Thermal Management Design:

To make the layout better we need to spread out the things that produce heat. This way the heat is not all, in one place. We should avoid having a lot of heat sources close together. This helps with layout optimization by dispersing heat sources and avoiding concentration of heat in one area. Layout optimization is important because it helps to disperse heat sources.

Material selection: High thermal conductivity substrates (e.g., aluminum, ceramic).

The structural design is really important. It has airflow channels. This helps to enhance the convection of the design. The structural design needs airflow to work well. Proper airflow channels, in the design are very useful. They help to make the convection of the design better.

EMI Suppression Strategies:

Source Control: Slow down switching edges (but increases switching loss).

Path Blocking: Common-mode/Differential-mode filters.

Structural Optimization: Reduce parasitic parameters, optimize PCB layout.

4. Practical Design Flow and Validation

4.1 Seven-Step Design Process

Requirement Analysis: Clarify all electrical specifications and environmental conditions.

Topology Selection: Based on the decision matrix in Section 2.1.

Component Selection: Detailed calculations for switches, inductors, capacitors.

Control Design: Compensation network design and stability analysis.

PCB Layout: Follow the golden rules of power layout.

Prototype Testing: Measurement and optimization of key parameters.

Reliability Validation: Environmental tests like high/low temperature, thermal cycling.

4.2 Key Testing Metrics

Efficiency Curve: Efficiency distribution at full, half, and light loads.

Thermal Imaging: Identifies hot spots, validates thermal design.

Dynamic Response: Overshoot/undershoot during load steps.

The EMI Spectrum is used to check if the EMI emissions are okay. The EMI Spectrum checks to see if the emissions that are sent through cables or go through the air meet the standards for EMI emissions. This is important for the EMI Spectrum to verify that the EMI emissions are safe and do not cause problems. The EMI Spectrum is used to make sure that the EMI emissions, from a device meet the standards.

5.Cutting-Edge Technologies and Future Trends

5.1 Integration Trend: From Discrete to Modular

Advantages of Power Modules:

Controllable parasitic parameters.

Simplified design process.

Faster time-to-market.

5.2 Intelligence Trend: From "Dumb" to "Smart"

Features of Intelligent Power Supplies:

Status Monitoring: Real-time reporting of temperature, current, efficiency.

Predictive Maintenance: Algorithm-based fault prediction.

Dynamic Configuration: Adjusts operating modes based on demand.

The Endless Pursuit of Efficiency

DC-DC converter design is a balancing act through and through. It’s all about striking the perfect chord between efficiency, cost, size, and reliability.

Emerging fields are advancing at breakneck speed—think new energy, electric vehicles, and 5G communications. Growing right alongside this progress is the demand for DC-DC converters that deliver high efficiency, high power density, and rock-solid reliability.

Share our interesting knowledge and stories on social media