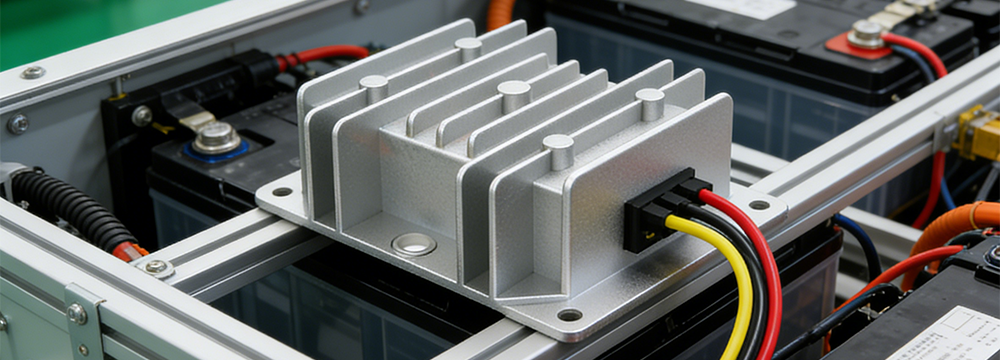

The complex operating conditions of industrial equipment (such as high temperatures, strong electromagnetic interference, and frequent load fluctuations) place stringent demands on the reliability of the power supply system. As the core component of power conversion, the proper selection of a DC-DC converter directly determines the stability of equipment operation. The following sections break down the selection logic from key dimensions to assist in accurate selection.

I. Clarifying Core Operating Requirements

First, you need to identify the core parameters of the industrial application. Included in these key specs are the input voltage range — such as wide fluctuations from battery supplies or unstable grid inputs — output voltage accuracy, rated power, and peak load. For precision control equipment, millivolt-level accuracy is a must. For heavy-duty devices like motors, instantaneous overload during startup also needs to be accounted for.

Equally critical is consideration of environmental limits. Take high-temperature workshops, for example, where temperatures can swing between -40℃ and 85℃. Or harsh settings with high humidity or heavy dust. Only products with a wide operating temperature range and a robust protection rating (IP54 and above) should be selected. These features can effectively prevent component aging and short-circuit failures that would otherwise disrupt operations.

II. Prioritizing Topology and Control Strategy Matching

The reliability and suitability of different topologies vary significantly: for heavy-duty industrial equipment (such as machine tools and frequency converters), full-bridge and half-bridge high-power topologies are preferred, offering both high conversion efficiency and impact resistance; for applications requiring electrical isolation (such as medical equipment and high-voltage industrial control), Flyback and Forward isolated topologies can prevent interference transmission; for wide input voltage range applications (such as new energy storage), SEPIC and Buck-Boost topologies can ensure stable output during voltage fluctuations. In terms of control strategies, high-frequency PWM control is suitable for high-precision requirements, PFM control is suitable for energy saving under light loads, and digital control is easier to implement intelligent fault diagnosis, improving long-term reliability.

III. Focusing on Key Performance and Protection Design

High-reliability DC-DC converters require strong anti-interference and fault tolerance capabilities: input and output terminals should integrate EMI filters to resist industrial electromagnetic radiation interference; high-quality components such as low ESR capacitors and high-precision inductors should be used to reduce ripple and noise; and over-voltage, over-current, and over-temperature protection functions should be included to prevent the spread of sudden failures. Furthermore, the vibration environment of industrial applications requires attention to the mechanical structure design of the product to ensure secure solder joints and stable component fixation.

IV. Verifying Brand and Compliance

Industrial equipment boasts an extended service life. Thus, choosing brands with a proven track record in the industry is critical.Prioritize verification of product certifications — CE, UL, and ATEX explosion-proof certifications among them. Only in this way can you ensure full compliance with industry safety standards.Factor in the supplier’s technical support capabilities as well. These capabilities are key to accommodating customized adjustments for complex operating conditions, thereby further bolstering the reliability of long-term equipment operation.

In summary, the key to selecting the right industrial-grade DC-DC converter lies in "operating condition suitability + performance redundancy + compliance assurance." Precisely identifying needs and scientifically selecting the topology and protection design are essential for building a robust power supply defense for industrial equipment.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

we can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media