In complex and demanding industrial environments, the power supply system is the "lifeline" for the stable operation of equipment. The DC-DC converter, as a core component of power conversion, directly determines the reliability of the power supply system and is a critical support for the continuous operation of industrial equipment and the seamless connection of production processes. Whether it's precision machine tools in intelligent manufacturing, energy storage equipment in the new energy sector, or heavy machinery in metallurgy and chemical industries, their operational stability highly depends on the efficient adaptation and reliable output of the DC-DC converter. It acts as a "central regulator" of the power supply system, building a stable defense line between harsh working conditions and diverse requirements.

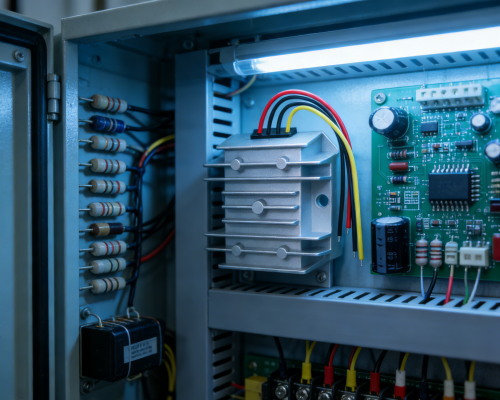

The extreme working conditions of industrial environments impose stringent requirements on power supply systems that far exceed those of the civilian sector. The core value of DC-DC converters is primarily reflected in their strong adaptability to harsh environments. Industrial equipment often faces wide voltage fluctuations, extreme temperature differences from -40℃ to 85℃, strong electromagnetic radiation interference, and complex environments with high humidity and dust. These factors can easily lead to abnormal power output, resulting in equipment downtime or malfunctions. DC-DC converters can achieve wide-range adaptation of input voltage through precise voltage regulation technology. Even when faced with fluctuations in battery power or unstable grid input, they can provide the load with stable electrical energy with millivolt-level accuracy and extremely low ripple, preventing voltage anomalies from damaging precision control modules and drive components. At the same time, high-quality industrial-grade DC-DC converters generally integrate multiple protection functions such as overvoltage, overcurrent, overtemperature, and reverse connection protection. Combined with professional anti-EMI filtering design and a robust structure with IP54 or higher protection rating, they can resist electromagnetic interference to power signals and isolate dust and moisture erosion, slowing down the aging of core components such as capacitors and inductors, effectively preventing the spread of single-point failures and ensuring the continuous operation of the power supply system in extreme environments.

The adaptability of the DC-DC converter's topology and control strategy further solidifies its core position in industrial power supply systems. Industrial equipment has vastly different requirements, from low-power supply for precision instruments to instantaneous high-load startup of heavy motors, each requiring different levels of power conversion efficiency, isolation performance, and impact resistance. DC-DC converters can adapt to various topologies such as full-bridge, half-bridge, flyback, and SEPIC, meeting diverse application scenarios: for heavy equipment such as machine tools and inverters, the full-bridge topology balances high conversion efficiency and strong shock resistance; for high-voltage industrial control and medical equipment requiring electrical isolation, flyback and forward topologies effectively block interference transmission; and for wide-voltage input scenarios such as new energy storage, the SEPIC topology ensures stable output even with voltage fluctuations. In terms of control strategies, high-frequency PWM control meets the high-precision power supply requirements of precision equipment, PFM control enables energy-saving operation under light loads, and digital control integrates intelligent fault diagnosis functions, monitoring operating status in real time and providing early warnings of anomalies, significantly improving the long-term reliability of the power system.

The continuity of industrial production directly determines production efficiency and profitability. The high reliability of DC-DC converters is a critical guarantee for production processes. Industrial equipment typically has a lifespan of several years or even decades, and DC-DC converters, as core consumable components, directly affect the overall maintenance costs and downtime losses of the equipment. High-quality DC-DC converters utilize high-quality components such as low-ESR capacitors and high-precision inductors, coupled with vibration-resistant mechanical structures, to effectively withstand vibration and shock in industrial environments, ensuring secure solder joints and stable component fixation, reducing failures caused by mechanical wear. Furthermore, compliance certifications and brand technical support ensure that DC-DC converters not only meet industry safety standards such as CE and UL, but can also be customized to adapt to special working conditions, further reducing the risk of power system failures and building comprehensive, multi-layered reliability protection for industrial power systems, becoming a core support for the steady progress of industrial production.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media