With the intelligentization of industrial equipment and the popularization of energy storage systems, DC battery chargers are being used in more and more scenarios—from power supply for AGV robots in workshops, to power supplementation for home energy storage, and maintenance of backup power supplies in base stations. However, many people either only look at the price or get confused by parameters when selecting a DC battery charger. As a result, the selected DC battery charger is either incompatible with the equipment or malfunctions soon after use. In fact, choosing the right DC battery charger is not difficult. By focusing on the following core dimensions, you can accurately find the product that suits you.

Compatibility

The first priority when choosing a DC battery charger is to ensure it is "compatible" with your battery. First, you need to clarify the battery type: lead-acid batteries and lithium batteries have completely different charging logics. For example, lead-acid batteries require a three-stage charging process of constant current - constant voltage - float charging, while lithium batteries require higher voltage accuracy. Using the wrong DC battery charger can lead to incomplete charging at best, and battery swelling or shortened lifespan at worst. Secondly, you need to match the voltage and current: the output voltage of the DC battery charger must be consistent with the battery's nominal voltage; the current should be based on the battery capacity, usually controlled between 10%-20% of the battery capacity. For example, for a 100Ah battery, a DC battery charger with a 10-20A output is more suitable, preventing both slow charging and battery damage due to current overload.

Conversion Efficiency

Many people overlook the conversion efficiency of DC battery chargers, but this is precisely the key to "hidden cost savings" in long-term use. An inefficient DC battery charger wastes a lot of electrical energy. For example, when charging a 100Ah battery, a product with 85% efficiency consumes nearly 10 more kWh of electricity than one with 90% efficiency, leading to a significant difference in electricity bills over time. Currently, the conversion efficiency of high-quality DC battery chargers can mostly reach over 90%, and some brands optimize energy consumption for different scenarios. For example, IDEALPLUSING has adjusted the layout of power modules in the circuit design of its DC battery chargers, allowing the equipment to maintain stable and high efficiency in both light-load and full-load conditions, making it suitable for industrial scenarios that require long-term charging.

Safety Protection

DC battery chargers are in direct contact with electrical energy, so safety protection is indispensable. A good DC battery charger comes with multiple protection functions: overcharge protection prevents continuous power supply to the battery after it is fully charged, avoiding overcharging and heating; short-circuit protection can quickly cut off power in case of accidental line short-circuit, preventing equipment burnout; overheating protection can cope with temperature rises in high temperatures or enclosed environments in summer, extending the lifespan of the DC battery charger itself. In addition, if the usage scenario has a large temperature difference (such as outdoor energy storage or cold chain workshops), it is recommended to choose a DC battery charger with temperature compensation function, which can automatically adjust charging parameters according to the ambient temperature, avoiding insufficient charging at low temperatures and overcharging at high temperatures.

Application Scenarios

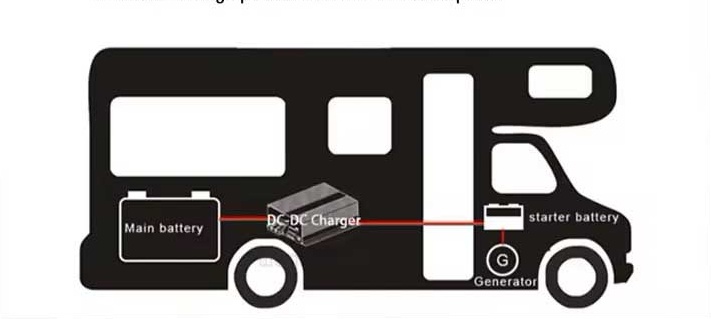

Different scenarios have significant differences in requirements for DC battery chargers. For example, AGV robots in industrial workshops require 24/7 continuous charging, so a DC battery charger with high-frequency use resistance and strong stability should be selected; home energy storage systems require DC battery chargers to support peak-valley electricity price adaptation, enabling more charging when electricity prices are low; the backup power supply of communication base stations may be in humid or dusty environments, so a DC battery charger with a high protection level should be chosen to ensure normal operation even in harsh environments. In short, first figure out what you need the DC battery charger for, then select it accordingly, to avoid the situation of "buying the wrong one and not being able to use it".

There is no need to pursue "more functions the better" when choosing a DC battery charger; instead, it should be "just suitable". As long as you first confirm compatibility, then pay attention to efficiency and safety, and finally match the usage scenario, you can find a cost-effective product. Brands like IDEALPLUSING, which focus on details in the field of DC battery chargers, are good at balancing compatibility and practicality, making them suitable for most daily and industrial scenarios. Remember, choosing the right DC battery charger can not only protect your battery and equipment but also reduce the trouble of subsequent maintenance, which is truly a "worry-free choice".

IDEALPLUISNG Power Expert:

We focus on the research and development, sales and services in the fields of DC-DC power modules, AC-DC rectifier modules, DC-AC inverters, AC power supplies, DC power supplies, LED power supplies, chargers, rectifier systems, etc., providing personalized, efficient, reliable and cost-effective power solutions for all walks of life.

Thank you for considering our services.