In the world of power electronics DC-DC converters are really important for getting energy where it needs to go and changing it into the form. The way DC-DC converters work has an effect on how well electronic devices use energy, how big they are and how reliable they are.DC-DC converters are used in lots of things like fast chargers for phones and laptops and power supplies in electric cars. They are also used in computer systems and, in devices that turn sunlight into energy.

DC-DC converters are used in different situations and people are always trying to make them work better. Gallium nitride is a good material for making things like DC-DC converters work better.It is helping these converters to be more efficient and smaller.Gallium nitride is a type of semiconductor material that's very good at handling high power.This is important because traditional materials like silicon are not working well as they used to.Gallium nitride is making a difference in the way we convert power.It is the start of an era, for high-efficiency and high-density power conversion using gallium nitride and gallium nitride devices.

I. Gallium Nitride: A Material Revolution Transcending Silicon-Based Limitations

To grasp how GaN enhances DC-DC converters, clarifying its intrinsic advantages over conventional silicon (Si) materials is paramount. The core performance of semiconductors is governed by bandgap width. GaN boasts a bandgap width of 3.45 eV, triple that of silicon (1.12 eV). This trait equips it with three "intrinsic merits," laying a solid groundwork for the performance leap of DC-DC converters.

First comes ultra-high switching speed. The electron saturation velocity of GaN is really high it can go up to 27-30 million centimeters per second. This is 2.7 to 3 times faster than silicon. GaN also does a job when it comes to electron mobility, which makes GaN devices switch on and off much faster than silicon devices. We are talking about 10 to 50 times faster.When we use GaN for DC-DC converters, the speed at which it switches on and off is very important. It affects how much energy is lost and how often it operates. If GaN devices can switch on and off quickly then we lose a lot energy each time we convert it. This means we can make high-frequency designs, which's a big advantage. GaN devices are really good, for this because they can switch on and off quickly.

Second is extremely low on-resistance loss. GaN features a critical electric field strength of 3.3 MV/cm, 11 times higher than that of silicon. This enables the device’s conductive layer to be made thinner under the same voltage rating. Its on-resistance can drop as low as 3-7 mΩ·cm², merely one-third to one-fifth of that of silicon devices. On-resistance loss ranks among the primary energy loss sources in DC-DC converters. Low on-resistance can notably boost conversion efficiency, particularly in high-current applications.

Third is exceptional thermal stability and voltage endurance. GaN devices can operate at temperatures exceeding 200°C, far surpassing the 125°C upper limit of silicon devices. They maintain stable performance in high-temperature environments, alleviating the design burden of cooling systems. Meanwhile, their high voltage endurance allows adaptation to medium and high-voltage DC-DC conversion scenarios, enabling high-voltage output without intricate series configurations.

II. Three Core Empowerments: Reshaping the Performance Landscape of DC-DC Converters

Based on the aforementioned material characteristics, GaN comprehensively empowers DC-DC converters from three dimensions—efficiency, power density, and system reliability—breaking the performance constraints of traditional silicon-based solutions.

1. Efficiency Leap: From "Energy Saving" to "Near-Lossless" Conversion

The energy loss of DC-DC converters mainly comes from on-resistance loss and switching loss. GaN devices achieve efficiency breakthroughs through dual optimizations. On the one hand, extremely low on-resistance significantly reduces on-resistance loss, with remarkable energy-saving advantages especially in continuous high-current output scenarios. On the other hand, ultra-fast switching speed shortens the overlap time of voltage and current, almost eliminating reverse recovery charge, reducing switching loss to less than 1/10 of that of silicon-based devices.

In practical applications, the full-load efficiency of DC-DC converters using GaN can easily exceed 97%, with peak efficiency approaching 98%.

2. Doubled Power Density: From "Bulky" to "Lightweight" Design

Power density is a key indicator for DC-DC converters, especially crucial in space-constrained scenarios such as consumer electronics and on-board equipment. The core advantage of GaN's high-frequency operation capability is that it can significantly reduce the size of passive components—the size of inductors and transformers is inversely proportional to the operating frequency. When the switching frequency is increased from tens of kilohertz (for silicon-based) to hundreds of kilohertz or even several megahertz (for GaN), the volume of magnetic components can be reduced by more than 30%-50%, and the capacitance requirement of filter capacitors is also significantly lowered.

Taking EPC's 6 kW DC-DC converter as an example, after adopting GaN devices, the overall board area is only 5000 mm², with a total thickness of 8 mm, and its power density is far higher than that of traditional silicon-based solutions. In the consumer electronics field, GaN fast chargers are 40% smaller than traditional silicon-based products, achieving the breakthrough of "small size and high power." In new energy vehicles, high-power-density DC-DC converters can save cabin space, supporting battery layout and vehicle lightweighting.

3. System Upgrade: Expanding Application Boundaries and Reliability

The high thermal stability and voltage resistance of GaN not only simplify the heat dissipation design of DC-DC converters but also expand their application boundaries. In high-temperature and high-voltage scenarios such as industrial control and new energy power generation, GaN DC-DC converters can operate stably without complex heat dissipation modules, with significantly improved reliability. Their high voltage resistance also supports high-voltage architectures such as 800V, simplifying the power supply path and reducing the number of conversion stages and components.

Meanwhile, the cascode and enhancement-mode HEMT structural designs of GaN devices are compatible with existing silicon-based drive circuits, lowering the threshold for system upgrades. For example, 650V enhancement-mode GaN HEMT devices are compatible with traditional silicon MOSFET drive logic, enabling rapid replacement without developing dedicated drive chips, thus accelerating the technological iteration of DC-DC converters.

III. Typical Application Scenarios: Practical Cases of GaN Empowerment

Today, GaN has been widely applied in various DC-DC converter scenarios, from consumer electronics to industrial-grade equipment, demonstrating strong adaptability.

In data centers and AI infrastructure, the 800V high-voltage power distribution architecture has become a trend, and GaN DC-DC converters are the core support. By directly converting 800V to 12.5V, it eliminates the traditional 54V intermediate conversion stage, not only improving efficiency but also reducing the board area by 26%, providing efficient power supply for high-performance chips such as GPUs and supporting megawatt-level power demand.

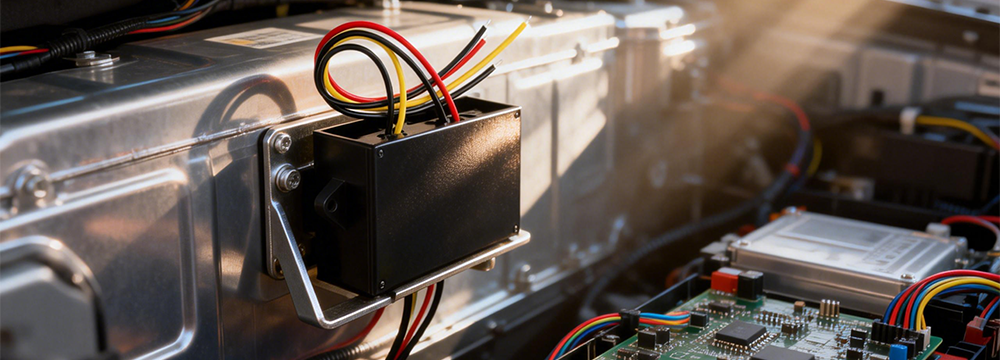

In the new energy vehicle field, GaN DC-DC converters can be applied to on-board chargers (OBC) and power battery management systems, realizing efficient energy conversion between high-voltage batteries and low-voltage on-board electrical appliances. Their high power density and thermal stability adapt to the complex operating environment of vehicles, while reducing energy consumption and improving cruising range.

In the consumer electronics field, GaN fast chargers have become mainstream. From mobile phones and laptops to tablets, GaN DC-DC converters have upgraded the user experience with "small size, high power, and low heat generation"—65W or even 100W fast chargers can fit in the palm of the hand.

IV. Challenges and Future: The Advanced Path of GaN Empowerment

Despite the significant empowering effects of GaN on DC-DC converters, large-scale applications still face certain challenges. Currently, GaN devices have issues such as complex drive circuit design, low gate threshold voltage prone to false conduction, and higher cost than silicon-based devices. However, with the iteration of dedicated drive chips and the improvement of wafer manufacturing yield, these bottlenecks are gradually being broken—GaN device prices are continuously decreasing, the system-level cost advantage is becoming increasingly prominent, and cost-performance balance has been achieved in mid-to-high-end applications.

In the future, GaN will drive DC-DC converters toward higher frequency, higher efficiency, and greater integration. On the one hand, the integration technology of wide-bandgap semiconductors will further improve power density, realizing the full-chain optimization of "device-module-system." On the other hand, the synergistic application of GaN and silicon carbide (SiC) will cover more voltage levels and power scenarios, providing more efficient power conversion solutions for new energy, artificial intelligence, Industry 4.0, and other fields.

The empowerment of DC-DC converters by GaN is essentially a power electronics technology upgrade driven by a material revolution. From reducing energy consumption and shrinking size to expanding application boundaries, GaN is breaking the performance ceiling of traditional silicon-based solutions, providing a more efficient and reliable energy conversion core for various electronic devices. With the continuous maturity of technology and cost reduction, GaN will become the mainstream choice for DC-DC converters, driving energy utilization into a greener, more compact, and smarter new era.

We at IDEALPLUSING not only provide products, but also strive to provide customers with suitable power supply solutions and quotations.

Our core competitiveness lies in carefully selecting a variety of power supply options to help customers evaluate and choose the most suitable power supply solution.

We can offer AC DC power supply, DC AC inverter, AC AC power source(single phase or 3 phases),AC DC Ground Power Unit...

Share our interesting knowledge and stories on social media